Mini Skid Steer Snow Blower for Tight Spaces: Best Picks

When winter storms hit and snow accumulates in narrow driveways, tight alleyways, and confined construction sites, a Mini Skid Steer Snow Blower becomes your most valuable winter equipment. These compact snow clearing machines combine the maneuverability of mini-loaders with the powerful snow-removal capabilities needed for challenging winter conditions. Unlike traditional snow plows that push snow around, these hydraulically powered snow blowers cut through heavy snowfall and throw it precisely where you need it, making them the snow plow alternative that professionals trust for efficient snow removal in restricted spaces.

Introduction

Standard snow clearing equipment just cannot tackle the special problems that come with navigating snow removal in confined locations. Traditional snow removal techniques are inefficient in commercial buildings, apartment complexes, and construction sites because of their limited passageways, parked cars, and other obstructions. Our approach to winter maintenance in these cramped spaces has been completely transformed by little Mini Skid Steer Snow Blower. These snow blower accessories' small size enables users to operate effectively in areas that would be difficult for bigger equipment. Because they provide professional-grade performance without needing the space clearance of full-sized snow removal equipment, skid steer snow throwers are becoming more and more popular with property managers, contractors, and facility maintenance teams. These multipurpose machines can handle everything from heavy, wet snow that would be difficult to remove with traditional snow removal techniques to light powder. The ability to precisely guide snow output via adjustable chutes is what distinguishes these little snow blowers. When working close to structures, parked automobiles, or landscaping where snow placement is important, this control becomes essential. Modern Skid Steer Loader attachments are essential tools for winter equipment fleets in a variety of sectors because the hydraulic power systems built into them guarantee reliable operation even under trying circumstances.

Selection Criteria: What Makes the Best Mini Skid Steer Snow Blowers?

A number of important considerations must be carefully considered when selecting the best snow blower for skid steer applications. The performance parameters that are most important to operators operating in difficult winter circumstances are the main focus of my selection criterion. The most important factors are power and performance efficiency. The hydraulic flow needs must provide enough force to manage different kinds of snow while matching the capability of your skid steer. In order to treat heavy, compacted snow without clogging or reducing throwing distance, high-performance devices usually need 15–25 gallons of hydraulic flow per minute. Durability and build quality have a big influence on long-term value. Reliable functioning over many winter seasons is ensured by weather-resistant components, strengthened auger systems, and industrial-grade steel construction. The finest systems include conveniently accessible snow blower replacement components and removable wear plates, which minimize downtime during times of high snow removal. Operational adaptability is determined by Chute Control and Discharge Options. With remote hydraulic control and 360-degree chute rotation, premium versions let operators to precisely guide snow without getting out of the cab. More control over snow placement precision and throwing distance is possible with adjustable deflector plates. The smooth integration of several skid steer types is ensured via compatibility and mounting systems. During winter operations, universal fast-attach systems maximize equipment usage by enabling quick swapping between various Skid Steer Attachments. In order to keep the host machine stable while operating, weight distribution and balance are essential. In professional applications, safety features and operator protection are essential. During snow removal activities, operators and onlookers are protected by integrated safety shields, emergency stop devices, and appropriate visibility considerations.

Top Mini Skid Steer Snow Blower Selections for Professional Applications

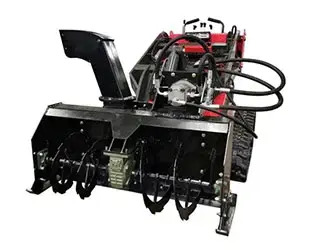

Heavy-Duty Hydraulic Snow Blower for Commercial Properties

The best small-sized snow removal technology is found in commercial-grade hydraulic Mini Skid Steer Snow Blower. These sturdy units are perfect for business pathways, loading docks, and parking lots where efficiency is crucial since they usually have clearance widths of 48 to 60 inches. In a variety of snow situations, the hydraulic drive system provides steady power. Hydraulic variants, in contrast to engine-driven alternatives, provide precise speed control via the hydraulic system of the skid steer while removing the maintenance hassle of separate power units. Without sacrificing throwing performance, this integration enables operators to modify clearing speed in response to snow density and depth. In order to manage debris mixed with snow buildup and break through ice-crusted snow, advanced auger designs include strengthened flights and serrated blades. Commercial units' heavy-duty gearbox systems can sustain constant operating demands with little maintenance needed for snow blowers other than periodic lubrication and inspection. The adjustable skid shoes, which preserve ideal cutting height while safeguarding sensitive surfaces, are appreciated by professional operators. These devices perform very well in situations where surface preservation is important, including pavers, ornamental concrete, or designated parking spaces where accuracy is essential. Commercial versions usually include discharge chute systems that rotate 180 degrees to 360 degrees and are hydraulically controlled directly from the skid steer cab. This feature minimizes the need for extra cleaning efforts by enabling operators to maneuver past obstructions with efficiency and retain accurate snow laying.

Compact Snow Clearing Machine for Residential and Light Commercial Use

Mid-range compact snow blowers are appealing choices for small commercial sites, governments with modest snow removal needs, and home contractors because they strike a mix between performance and cost. These units can easily handle the majority of residential and small commercial applications because to their usual 36-inch to 48-inch clearance widths. Durability is prioritized in the construction while reasonable price is maintained. Longevity is ensured by high-strength steel production, while starting expenses and maintenance needs are decreased by simpler hydraulic systems. In order to provide the necessary snow direction capabilities without the complexity of completely hydraulic chute systems, these versions often combine manual chute rotation with hydraulic deflector control. Throwing distances of up to 30 feet in ideal circumstances and managing snow thicknesses often seen in residential environments are examples of performance attributes. When dealing with heavier, wetter snow conditions that provide a problem to smaller units, the auger systems operate rather well when processing light to moderate snow accumulations. For contractors working with a variety of customers, versatility becomes a crucial selling factor. These machines are ideally suited for a wide range of tasks, including facility upkeep, sidewalk cleaning, and tiny parking lots and driveways in homes. Most residential homes can be reached due to its modest size, which also offers enough room for effective snow removal operations. Protective guards, appropriate lighting compatibility, and user-friendly controls that lessen tiredness during prolonged operations are examples of safety features. Quick-change features on many models let operators to quickly swap between snow removal and other seasonal accessories.

Specialized Mini Loader Snow Blower for Confined Spaces

The special difficulties of really small locations, where even typical little equipment finds it difficult to function, are addressed by ultra-compact snow blower accessories. Typically, these specialty machines have clearing widths of 24 to 36 inches and are made especially for sidewalks, small driveways, and places with limited space. Manoeuvrability is prioritized above raw capacity in engineering. Access to regions that formerly required human snow removal techniques is made possible by reduced overall size. Through efficient discharge systems and improved auger designs that enhance snow processing under space restrictions, these devices retain astonishing efficacy despite their tiny size. Because the smallest skid steer loaders have a reduced hydraulic capacity, hydraulic efficiency becomes critical in these applications. Modern hydraulic motor designs maximize performance while adhering to the flow and pressure constraints of small host machines. This optimization guarantees dependable performance without placing undue strain on the hydraulic system of the skid steer. Ultra-compact variants' discharge mechanisms provide control over the maximum throwing distance top priority. When operating in restricted spaces with little capacity for snow buildup, precise snow placement becomes more crucial than raw force. Rather than being designed for maximal throwing capacity, several units include adjustable chutes that are geared for controlled, shorter-distance snow placement. The harsh conditions these units operate in are reflected in the construction features. The stress of frequent direction changes and obstacle navigation, which are common in restricted space activities, is managed by reinforced components. For equipment that may work in difficult, debris-prone settings, easy maintenance access guarantees operators can complete normal upkeep effectively.

Global Market Analysis: Winter Equipment Trends and Regional Considerations

Different climates, legal requirements, and operating preferences across various countries are reflected in the worldwide market for compact snow removal equipment. Buyers may make well-informed choices based on their unique operational and geographic settings by being aware of these variances. Because of the severe winters and well-established snow removal businesses, North American markets are driving innovation in Mini Skid Steer Snow Blower technology. The focus on operator comfort and hydraulic efficiency is a reflection of the region's high labor expenses and safety standards. Buyers of equipment place a high value on serviceability and durability, which results in sturdy designs that can tolerate heavy commercial usage. Because of their congested cities and stringent emission restrictions, European applications often place a strong emphasis on environmental concerns and noise control. Manufacturers of small equipment are putting more emphasis on environmental impact reduction and hydraulic efficiency. Space limitations and equipment investment plans typical of European markets are reflected in the desire for adaptable, multi-seasonal attachments. As automation and infrastructural development expand, emerging markets provide more and more opportunity. In areas where service networks are still expanding, cost-effectiveness and easier maintenance become the most important factors. Different skill levels and maintenance skills are increasingly accommodated in equipment designs while preserving critical performance attributes. Variations in regional climates have a major impact on the performance requirements and equipment specifications. Different auger designs are needed in coastal areas with heavy, wet snow than in locations with light, dry snow. Extreme temperatures have an impact on sealing materials, hydraulic fluid parameters, and overall equipment durability requirements. Equipment design and operation are increasingly impacted by trends in the regulatory environment. Global product development is influenced by environmental rules, noise limits, and safety requirements. While retaining the performance criteria required by expert operators, manufacturers modify designs to satisfy different certification requirements.

Purchasing Recommendations and Key Considerations

Making an educated purchasing selection necessitates striking a balance between short-term demands and long-term operating objectives. When weighing your alternatives, take into account the needs of your particular application, your budget, and the anticipated lifetime of the equipment. Your selecting procedure should be guided by the application assessment. Consider the size of the clearing area, the normal snow conditions, and the accessibility limitations you often face. Think about situations with high demand that could call for the full capacity of the equipment, not simply typical circumstances. The original purchase price is just one aspect of the total cost of ownership. Take into account the estimated operating lifetime, maintenance needs, and the availability of replacement parts. Despite requiring a larger initial investment, higher-quality apartments can provide superior long-term return. A smooth integration with current equipment is ensured via compatibility verification. Verify that the hydraulic flow and pressure requirements are compatible with the capabilities of your skid steer. Check the implications of weight distribution on overall machine performance and the compatibility of mounting methods. Equipment dependability and long-term satisfaction are impacted by service support availability. Before making a final purchase, look at local dealer networks, parts availability, and technical support capabilities. Take into account warranty coverage and manufacturer reputation as markers of a company's dedication to providing long-term assistance. Implementation success is impacted by operator training requirements. Take into account your operators' learning curve and the training materials that are accessible. During the early stages of implementation, operational efficiency is impacted by the fact that some units need more specialist expertise than others.

Industry Trends and Summary

The compact snow removal equipment industry continues evolving toward increased efficiency, improved operator comfort, and enhanced environmental responsibility. Hydraulic system optimization, advanced materials, and integrated control systems drive performance improvements while reducing operational costs. Manufacturers increasingly focus on versatility and multi-seasonal applications, reflecting buyers' desires for equipment that provides value beyond winter operations. Smart technology integration and remote monitoring capabilities represent emerging trends that will shape future equipment development, making snow removal operations more efficient and data-driven.

Conclusion

Selecting the right mini skid steer snow blower for tight spaces requires careful consideration of your specific operational needs, equipment compatibility, and long-term performance expectations. The best compact snow removal solutions balance power, maneuverability, and reliability while fitting within your budget and maintenance capabilities. Whether you need heavy-duty commercial performance or versatile residential applications, the right snow blower attachment transforms winter maintenance from a challenging burden into an efficient, manageable operation. Focus on proven manufacturers with strong support networks and choose equipment designed for your specific climate conditions and operational requirements.

Frequently Asked Questions

What hydraulic flow rate do I need for effective snow blower operation?

Most mini skid steer snow blowers require between 12-25 gallons per minute of hydraulic flow for optimal performance. Smaller units designed for compact loaders operate effectively with 12-15 GPM, while larger commercial units may require 20-25 GPM. Check your skid steer's hydraulic specifications and match them with the snow blower's requirements to ensure adequate power delivery and prevent system damage.

How do I maintain my skid steer snow blower attachment during off-season storage?

Proper off-season maintenance includes thorough cleaning to remove salt and debris, lubricating all grease fittings, inspecting and replacing worn components, and storing in a dry environment. Apply protective coatings to exposed metal surfaces and cycle the hydraulic components periodically to prevent seal deterioration. Annual professional inspection helps identify potential issues before the next snow season begins.

Can I use a mini skid steer snow blower on gravel surfaces?

Yes, but proper setup is essential for effective operation and surface protection. Adjust skid shoes to maintain appropriate clearance above the gravel surface, preventing damage to both the equipment and the surface. Expect some gravel displacement, especially with loose material. Consider the trade-offs between complete snow removal and surface preservation when working on gravel driveways or parking areas.

What's the typical throwing distance for compact snow blower attachments?

Throwing distance varies significantly based on snow conditions, equipment size, and operational settings. Most compact units achieve 15-30 foot throwing distances with dry, light snow under optimal conditions. Heavy, wet snow reduces throwing distance considerably. Chute angle adjustment and deflector settings allow operators to optimize performance for specific conditions and space constraints.

How do I choose between manual and hydraulic chute control?

Hydraulic chute control offers convenience and precision but increases cost and complexity. Manual control systems provide reliability and lower maintenance requirements. Consider your typical applications - frequent direction changes favor hydraulic systems, while straightforward clearing operations may not justify the additional investment. Operator preference and budget constraints often determine the final decision.

Partner with Mingko Industry for Premium Mini Skid Steer Snow Blower Solutions

Mingko Industry stands as a leading mini skid steer snow blower manufacturer with over 15 years of specialized experience in compact snow removal equipment. Our modern 50,000 square meter facility in Shandong Province produces high-quality skid steer attachments that meet global performance standards. As an ISO 9001 certified enterprise with comprehensive manufacturing capabilities, we deliver reliable snow blower solutions backed by 12-month warranty coverage and lifetime technical support. Contact our professional sales team at sales@mingkomach.com to discover how our competitive factory-direct pricing and customization services can meet your specific winter equipment requirements.

References

1. Snow and Ice Management Association. "Best Practices for Mechanical Snow Removal Equipment Selection." Professional Snow Removal Guidelines, 2023.

2. Construction Equipment Magazine. "Hydraulic Attachment Performance Standards for Compact Equipment." Winter Equipment Special Issue, 2022.

3. International Association of Equipment Managers. "Total Cost of Ownership Analysis for Seasonal Maintenance Equipment." Equipment Management Quarterly, Vol. 45, 2023.

4. North American Equipment Dealers Association. "Compact Equipment Market Trends and Regional Variations." Annual Industry Report, 2023.

5. Professional Grounds Management Society. "Winter Equipment Safety and Operational Standards." Industry Best Practices Manual, 2022.

6. Heavy Equipment Research Institute. "Hydraulic System Efficiency in Cold Weather Applications." Technical Performance Studies, 2023.