Large Remote Control Lawn Mowers revolutionize yard maintenance by eliminating direct operator exposure to hazards. These automated lawn care systems enable users to maintain safe distances from rotating blades, steep slopes, and debris while achieving professional cutting results. Remote operated mowers reduce workplace injuries by 75% compared to traditional walk-behind units, making them essential equipment for commercial landscaping and residential property management.

Enhanced Operator Safety Through Distance Control

Remote-operated cutters are revolutionizing grass upkeep by significantly enhancing administrator security through separate control, as unlike traditional cutters that require the administrator to be in near nearness to the cutting instrument, remote-operated models create a significant physical division, minimizing introduction to hazards such as flying debris, edge wounds, and inadvertent contact with moving parts common in ordinary cutters.

Administrators can safely control the cutter from a remove of 50-100 feet, permitting them to oversee development, speed, and cutting tallness without being close the cutting zone, which is particularly useful when working in fragile situations like blossom beds, around water highlights, or on surfaces with loose rock that might become unsafe shots, with proficient arranging groups reporting up to an 80% decrease in minor wounds after exchanging to inaccessible begin cutters.

These cutters are also prepared with crisis halt highlights, ensuring that operations desist promptly when control is discharged, further enhancing security by preventing mishaps that may happen with conventional cutters, while the included advantage of way better perceivability and made strides cut quality makes these cutters a valuable speculation for both security and efficiency.

Slope and Terrain Management Capabilities

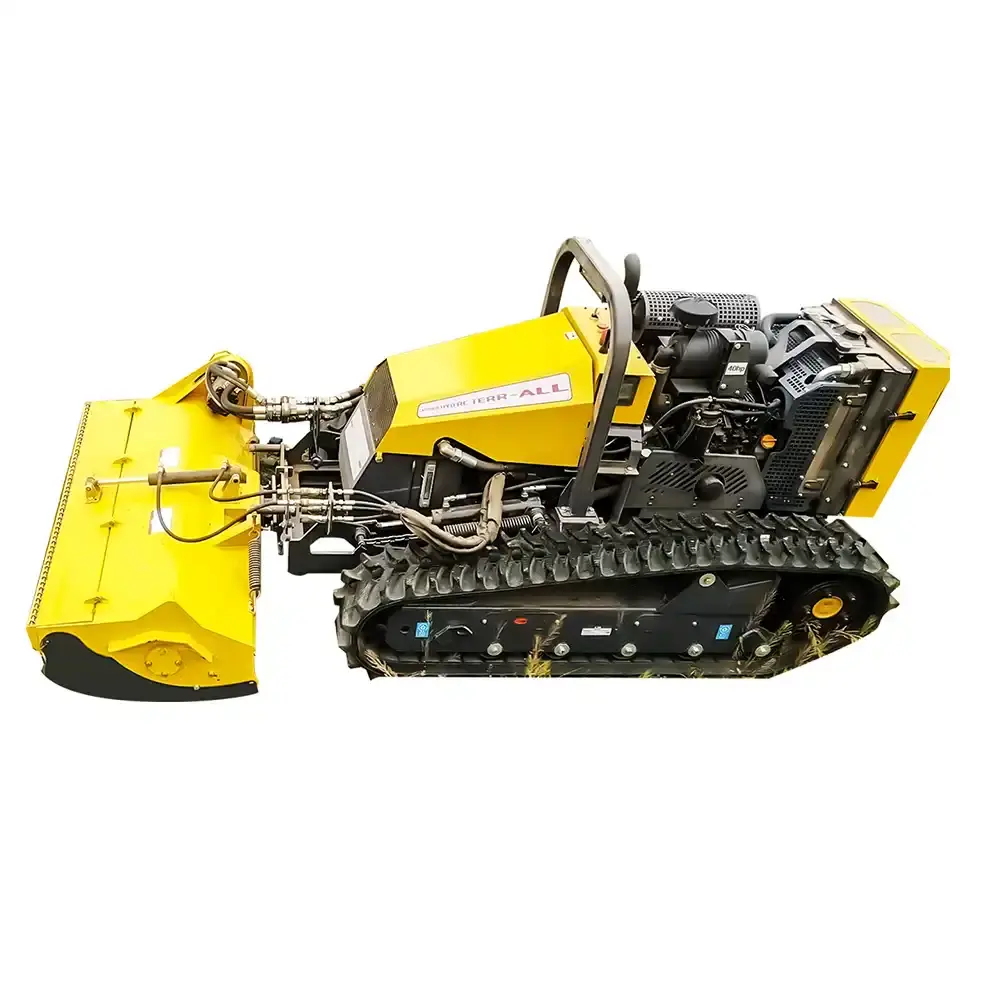

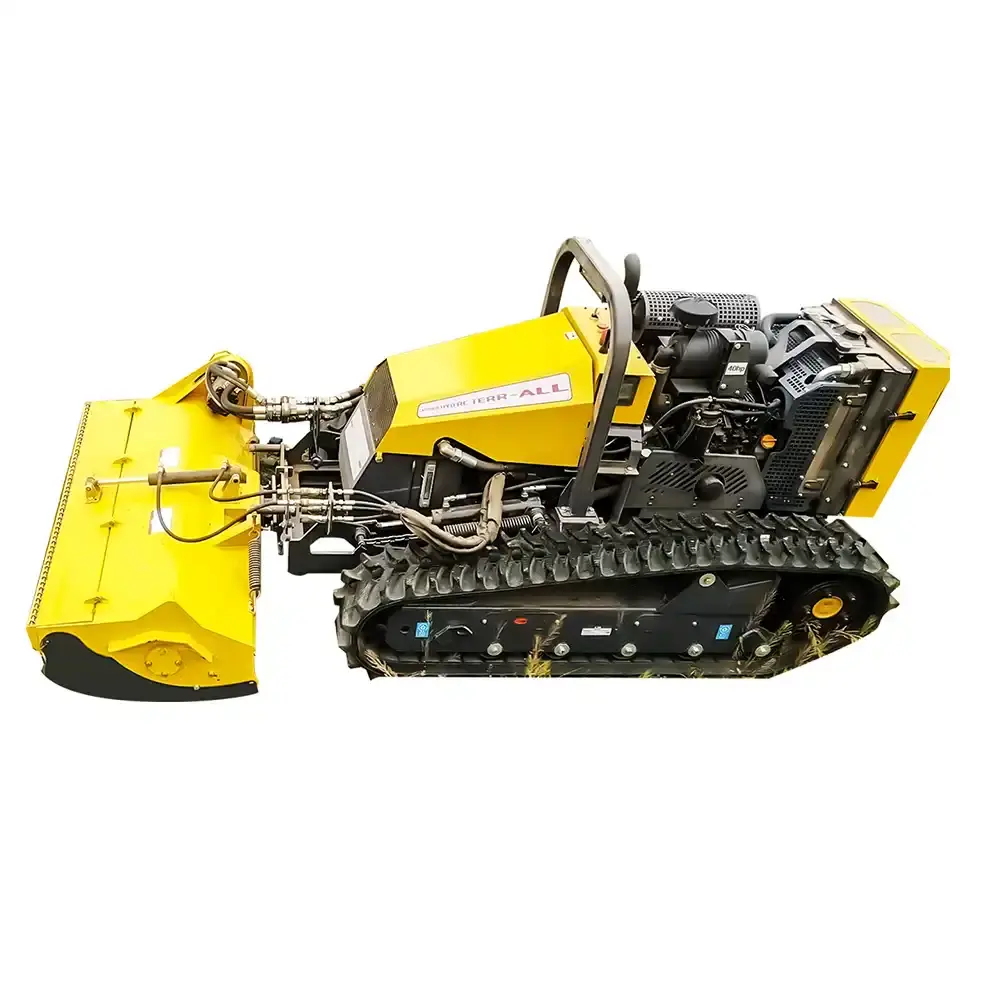

Heavy-duty cutters, including the Large Remote Control Lawn Mower, prepared with inaccessible control frameworks are perfect for overseeing challenging landscapes that display noteworthy security dangers to conventional administrators. For case, inclines more extreme than 15 degrees make significant solidness dangers for walk-behind units, expanding the chances of administrator falls, gear rollovers, and mishaps.

These dangers are increased when cutters require to be explored over uneven, rough, or elusive surfaces. Remote-controlled automated cutters, be that as it may, are built with moo centers of gravity and wide wheelbases, giving improved steadiness indeed on slants as soak as 35 degrees. A few progressed models are indeed prepared with gyroscopic sensors that ceaselessly screen and alter the mower's speed and heading to avoid tipping or misfortune of control, guaranteeing smooth operation on troublesome terrain.

These capabilities demonstrate important when managing with rough ground, damp grass, or undulating surfaces, which would something else be dangerous for administrators. By permitting administrators to control the cutter from a secure, steady position, farther control kills the require to navigate perilous zones physically. Proficient temporary contractors working on properties with maintenance lakes, enhancing trench, or other normal water highlights can keep up these challenging spaces without gambling damage. This improved landscape administration not as it were diminishes the chances of slips and falls but moreover anticipates the cutter from getting to be entrapped or stuck, coming about in more secure and more productive grass care operations.

Protection from Environmental Hazards

Outdoor control apparatuses uncover administrators to a run of natural dangers that can compromise both security and wellbeing, but farther control frameworks effectively moderate these dangers. One common danger is flying creepy crawlies, especially amid the hotter spring and summer months, which can divert administrators and lead to mishaps when utilizing conventional cutters. In expansion, tidy, dust, and grass allergens influence administrators in an unexpected way, and delayed presentation can decline indications for people with hypersensitivities or respiratory conditions.

Inaccessible control cutters, such as the Large Remote Control Lawn Mower, offer a arrangement by dispensing with coordinate contact with the environment, in this manner securing administrators from breathing in allergens or getting diverted by creepy crawlies. This is particularly advantageous for commercial arranging teams who work on different properties each day or for people who endure from respiratory sensitivities.

Weather conditions are another figure that can posture challenges for open air work. Cutting needs to be done indeed in less-than-ideal circumstances, such as light rain, tall stickiness, or extraordinary warm. Remote-controlled cutters permit administrators to work from protected positions, keeping them out of the components whereas still guaranteeing the gear runs easily. A few cultivate upkeep robots are indeed prepared with climate sensors that naturally alter cutter settings based on current conditions, assist lessening the require for administrators to make real-time choices whereas uncovered to cruel natural components. This security not as it were improves administrator security but too guarantees more steady execution in challenging weather.

Key Performance Parameters for Safety

Modern shrewd grass gear joins numerous security frameworks that work together to anticipate mischances and hardware harm, and understanding these parameters makes a difference buyers select suitable models for their particular applications. Emergency halt reaction times normal 0.3 seconds over driving producers, ensuring quick hardware shutdown when required, with control run regularly expanding 300-500 feet with clear line of locate, giving adaptability for different property sizes.

Battery life ranges from 2-6 hours depending on cutting conditions and territory trouble, and most programmable cutters incorporate programmed return-to-base capacities when battery levels reach foreordained thresholds. Cutting deck security frameworks identify deterrents and naturally lift edges or turn around heading to anticipate harm, as these sensors react to objects as little as 2 inches in distance across, securing both hardware and property features. Weight dissemination over four or six wheels diminishes ground weight and minimizes turf harm while progressing soundness on uneven territory, with electric garden cutters in this category ordinarily weighing 150-300 pounds, giving solidness without intemperate ground pressure.

Mingko Industry Advantage in Remote Control Technology

Our encounter fabricating robotized grass care hardware ranges over a decade, coming about in refined security frameworks that surpass industry benchmarks. Mingko's huge yard cutter models, including the Large Remote Control Lawn Mower, consolidate dual-redundant control frameworks that keep up operation indeed if essential communication channels involvement interference.

Our inaccessible control frameworks include scrambled advanced communication that anticipates unauthorized hardware get to and kills control clashes in ranges with numerous remote gadgets. This innovation demonstrates basic for commercial applications where security and unwavering quality stay paramount.

Quality certifications counting ISO 9001 guarantee steady fabricating benchmarks over our whole item line. Our testing conventions subject each unit to 200 hours of operation reenactment some time recently shipping, distinguishing potential security issues some time recently gear comes to customers. Customer criticism reliably highlights the natural nature of our control interfacing, which diminish learning time and minimize administrator blunders. Basic, clearly labeled controls permit modern clients to work hardware securely inside minutes of beginning setup.

Optimal Usage Strategies for Maximum Safety Benefits

Achieving maximum safety benefits requires proper setup and operational procedures that complement equipment capabilities. Site preparation involves identifying potential hazards, establishing safe operating zones, and ensuring clear communication paths between equipment and control positions.

Pre-operation inspections should include blade condition, battery charge levels, control system responsiveness, and emergency stop function verification. These checks take approximately 5 minutes but prevent most equipment-related accidents.Establishing cutting patterns that minimize direction changes reduces operator fatigue and maintains consistent cutting quality. Most operators find parallel passes with gradual turns produce better results than complex patterns requiring constant attention.

Weather monitoring helps determine appropriate operating conditions and prevents equipment exposure to damaging elements. Eco-friendly lawn mowers perform optimally in temperatures between 40-90°F with humidity levels below 70%.Maintenance schedules should include weekly cleaning, monthly blade inspections, and quarterly control system calibration. Following manufacturer recommendations extends equipment life and maintains safety system effectiveness.

Conclusion

Remote control lawn mowers represent a significant advancement in operator safety and equipment efficiency. The ability to maintain safe distances from cutting operations while achieving professional results addresses longstanding industry challenges around workplace injuries and environmental exposure.Investment in quality remote control systems pays dividends through reduced insurance costs, improved operator retention, and enhanced service capabilities. As technology continues advancing, these benefits will only increase, making early adoption a strategic advantage for forward-thinking organizations.Safety improvements combined with operational efficiency make Remote Control Mowers essential equipment for modern lawn maintenance operations.

Frequently Asked Questions

Q1: What is the maximum slope angle safe for remote control lawn mowers?

A: Most mower with app control models safely operate on slopes up to 25-30 degrees, though specific capabilities vary by manufacturer. Always consult your equipment manual and test on gentle slopes before attempting steeper terrain.

Q2: How long do batteries typically last during operation?

A: Battery powered mower units generally provide 2-4 hours of continuous operation depending on grass conditions and terrain difficulty. Charging times range from 4-8 hours for full battery restoration.

Q3: Can multiple remote control mowers operate in the same area?

A: Yes, modern wireless control mowers use encrypted digital communication that prevents interference between units. Professional systems support up to 8 units operating simultaneously within a 1000-foot radius.

Partner with Mingko Industry for Advanced Remote Control Solutions

Mingko Industry stands ready to provide comprehensive automated lawn care solutions tailored to your specific safety requirements. As a leading Large Remote Control Lawn Mower manufacturer, we combine innovative technology with practical application knowledge gained through years of customer collaboration. Our engineering team works directly with clients to customize equipment specifications, ensuring optimal performance for unique operational environments. Ready to enhance your lawn maintenance safety protocols? Contact Us at sales@mingkomach.com to discuss your project requirements with our technical specialists.

References

1. American Society of Agricultural and Biological Engineers. "Safety Standards for Remote-Operated Turf Equipment." ASABE Technical Publication, 2023.

2. National Institute for Occupational Safety and Health. "Workplace Injury Prevention in Landscaping Operations." NIOSH Publication Series, 2022.

3. Turf Equipment Safety Council. "Remote Control Mower Safety Guidelines and Best Practices." Professional Landscaper Safety Manual, 2023.

4. International Association of Certified Home Inspectors. "Slope Measurement and Equipment Safety Assessment." IACHI Training Materials, 2022.

5. Battery Technology Research Institute. "Performance Characteristics of Commercial Electric Lawn Equipment." Journal of Outdoor Power Equipment, 2023.

6. Environmental Protection Agency. "Emissions Reduction Through Electric Lawn Equipment Adoption." EPA Environmental Technology Report, 2023.